Designed for automated, high-speed packaging of diverse products. Automatically completes: carton formation; product loading; leaflet insertion; batch printing & sealing. Enhances efficiency and consistency.

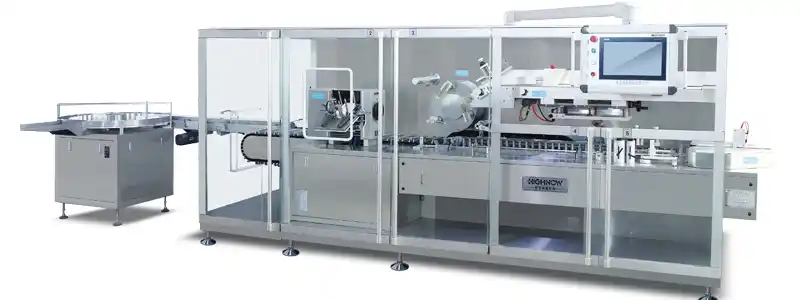

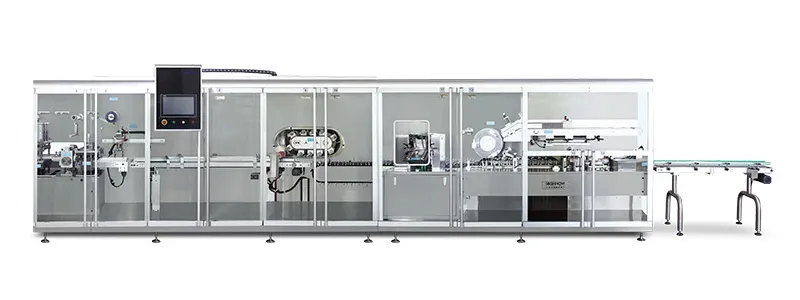

Automatic Cartoning Machine

Designed for automated, high-speed packaging of diverse products. Automatically completes: carton formation; product loading; leaflet insertion; batch printing & sealing. Enhances efficiency and consistency.

Engineered for versatility, the ZHJ-500SF High-Speed Automatic Cartoning Machine ensures process-safe, efficient packaging with fast changeovers and an interchangeable closing station, adapting seamlessly to diverse product lines.

The ZHJ-500 Fully-Automatic Cartoning Machine automates the entire process from leaflet folding to box sealing, offering reliable and versatile packaging for blisters, bottles, and vials, with easy integration into existing production lines.

Designed for ease and efficiency, the ZHJ-400SZ High-Speed Pharmaceutical cartoning machine enables fast format changes and features excellent accessibility for cleaning. Its smart control system automatically diagnoses stoppages, ensuring a smooth and user-friendly operation.

Combining intelligent 100% fault detection with flexible product handling, the ZHJ-400SF Linkage Line delivers unmatched process reliability and traceability for diverse pharmaceutical packaging needs.

The ZHJ-400 Automatic High Speed Cartoning Machine delivers uncompromising efficiency and process-safe reliability for diverse packaging needs, all through user-friendly operation and a quiet, protected design.

The ZHJ-120CA, HIGHNOIW's most compact intermittent motion cartoner, is expertly engineered for reliable vial stuffing and boxing, offering superior process reliability and a long service life for small to medium batch production.

HIGHNOW implements an end-to-end traceability system governing every production step from raw materials to finished goods; its digital management system assures 100% quality compliance.

We offer after-sales support to keep your production going.

This includes online advice 24/7, on-site commissioning, GMP guidance, fast response and plenty of spare parts.

Absolutely. We insist on a No-Obligation Performance Validation Test at our application lab. You send us your actual product (blisters, vials, syringes, etc.) and carton blanks. We will run a comprehensive test on the HIGHNOW machine, measuring critical metrics like carton erection success rate (>99.5%), product loading accuracy, and overall line efficiency. You will receive a full Validation Report with high-speed video analysis demonstrating the machine's capability with your materials. This de-risks your capital investment and provides undeniable proof of performance, a decisive factor for final decision-makers.

Energy efficiency and operator ergonomics are key considerations. The HIGHNOW cartoner, utilizing efficient servo motors and regenerative drives, has an average power consumption of 5-8 kW/h during standard operation, significantly lower than older mechanical models. Regarding noise, the machine operates at below 70 dB(A) at a distance of 1 meter, which is within the safety limits for an 8-hour exposure without mandatory hearing protection. This creates a better working environment and reduces energy costs, appealing to those searching for "energy efficient low noise cartoning machine".

Our HIGHNOW Uptime Guarantee Program is designed for maximum production reliability. The comprehensive SLA includes:

Remote Diagnostics: 24/7 secure VPN access for real-time troubleshooting and support.

Spare Parts Commitment: We guarantee shipment of critical spare parts within 24 hours, backed by a 99% parts availability rate from our global hubs.

On-Site Support: A committed response time of 48 hours for a certified engineer to be on-site for issues requiring physical intervention.

This program is specifically designed to minimize downtime and provide peace of mind, answering the critical query "automatic cartoning machine service support SLA".

Seamless integration is a standard feature. The HIGHNOW cartoner is equipped with industry-standard Allen-Bradley or Siemens PLCs and communicates via EtherNet/IP and OPC UA protocols. We design and supply custom inter-feed conveyors, accumulation tables, and buffering systems to create a synchronized packaging line. We conduct pre-delivery integration tests (virtual and physical) with your specified upstream and downstream equipment models to eliminate bottlenecks and ensure smooth material flow, directly addressing the critical need for "integrated packaging line cartoning machine".

Handling fragility is a specialty. We employ a gentle, servo-driven robotic pick-and-place or a custom-designed flight system that can be programmed with specific acceleration and deceleration profiles to cradle products. For irregular shapes, we develop custom-designed grippers or product-specific nests. The machine's vision system can verify correct product orientation before loading. This multi-faceted approach ensures a damage rate of less than 0.01%, even for delicate items like pre-filled syringes or medical devices, making it the ideal solution for those searching for "gentle handling cartoner for fragile products".

We believe in financial transparency. Our proprietary HIGHNOW TCO/ROI Calculator provides a granular analysis based on your inputs:

Capital & Operational Costs: Machine price, estimated energy consumption (~5-8 kW/h), and preventive maintenance costs.

Savings & Gains: Labor reduction (typically from 2-3 operators to 1), reduced material waste from high-accuracy placement (<0.1% waste), and increased output from higher OEE.

The model calculates your payback period, typically under 24 months, and a 5-year TCO, providing a clear financial justification that answers searches for "ROI automatic cartoning machine".

Designed for the most demanding environments, the HIGHNOW cartoner features a stainless steel AISI 304 (or optional 316L) frame with all product-contact surfaces polished to a Ra ≤ 0.6 µm finish. The design is hygienic and open, with rounded corners and sloped surfaces for positive drainage. Critical areas are protected by IP65-rated stainless steel electrical panels. The machine supports easy and rapid disassembly for cleaning with tool-less access to product zones. This comprehensive approach ensures adherence to cGMP, FDA, and EU Annex 1 standards, directly addressing concerns for "GMP washdown automatic cartoning machine".

Our integrated HIGHNOW Data Management System is built for full regulatory compliance in pharmaceutical and medical device packaging. The system enforces role-based user access control, maintains a complete and immutable electronic audit trail for all parameter changes and operational events, and supports electronic batch records. All data is securely stored in an encrypted SQL database. We provide a full suite of IQ/OQ documentation that specifically validates the system against FDA 21 CFR Part 11 requirements, ensuring your packaging line passes rigorous audits and targets high-value searches like "FDA 21 CFR Part 11 compliant cartoner".

Changeover efficiency is a core design principle. The HIGHNOW cartoner utilizes a fully servo-driven, recipe-based adjustment system. An operator selects the new product recipe from the HMI, which automatically positions all servo axes. Physical changeover involves swapping quick-release, modular carton magazines and product flights without tools. A complete changeover, including both carton size and product, is typically achieved in under 10-15 minutes. We supply digital, animated work instructions on the HMI and QR codes on the machine that link to video guides, ensuring repeatable and error-free operations while targeting key search terms like "quick changeover automatic cartoning machine".

Our HIGHNOW Automatic Cartoning Machines are engineered for robust, high-speed performance, with standard models operating at 100, 200, and up to 350 cartons per minute. However, we focus on sustainable OEE rather than peak speed alone. Our machines are designed to achieve an OEE consistently above 90% in validated production environments. This is accomplished through a servo-driven main drive system with an MTBF (Mean Time Between Failures) exceeding 20,000 hours, and features like a < 15-minute quick changeover system. We provide a detailed OEE Validation Report with each proposal, documenting performance metrics like Availability, Performance Rate, and Quality Rate during FAT (Factory Acceptance Testing), giving you a realistic projection of ROI.

We enforce strict quality checks from sourcing to assembly, including material tests, precision machining validation, and full performance testing before shipment.

Yes, we provide retrofitting solutions and hardware/software upgrades to scale your machine’s performance as your business grows.

We offer a standard 12-month warranty covering parts and manufacturing defects, extendable based on agreement.

We offer EXW, FOB, or CIF shipping terms and support with documentation for smooth customs clearance.

HIGHNOW provides comprehensive pre-sales support, including on-site facility assessments, production layout planning, and tailored equipment recommendations based on client requirements (e.g., output, stability). We also share technical parameters and arrange visits to existing client sites for verification.