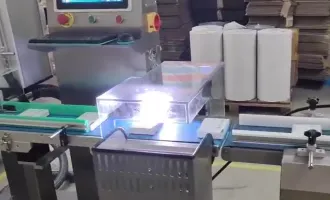

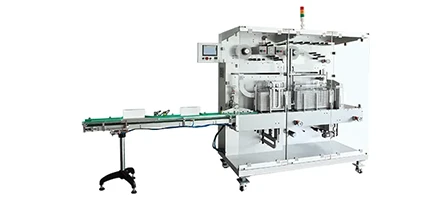

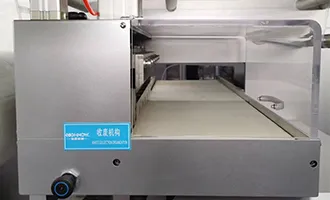

This is a cold water plate, installed in the laminating (PE, tinfoil, aluminum film), the cold water plate will be automatically inserted between the heat sealing molds during the shutdown, to isolate the temperature, to prevent the shutdown time is too long, the quality of the liquid in the bottle ...

-

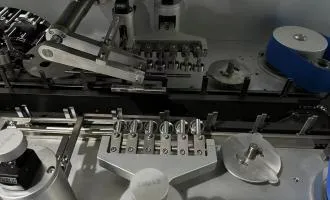

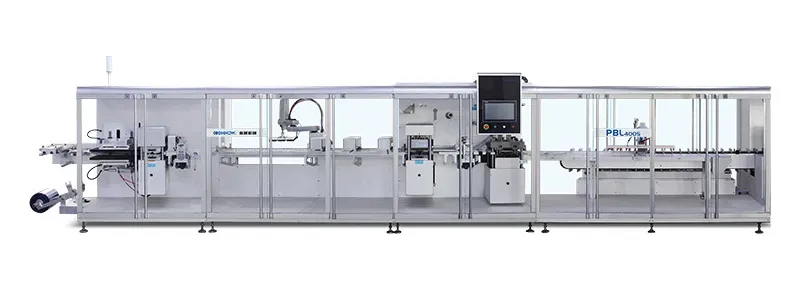

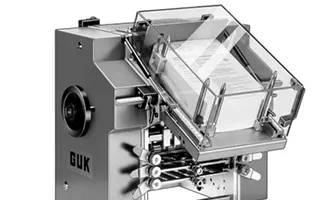

Punching frequency:

16-30 times / minute 1-4 plates / time -

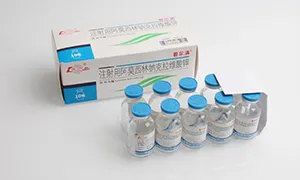

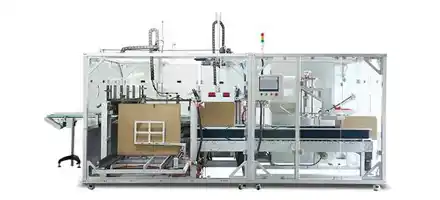

Boxing capacity:

250 boxes / min

.webp)