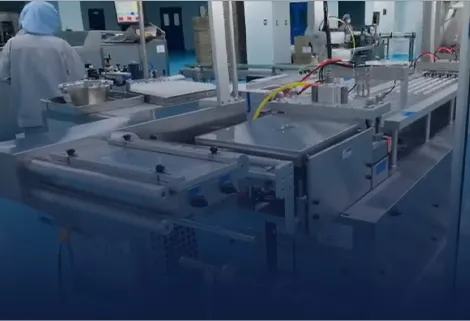

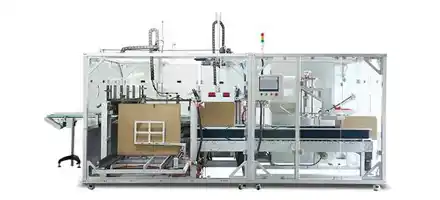

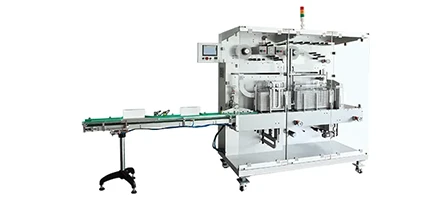

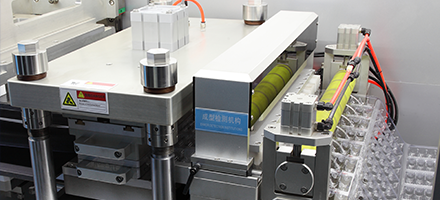

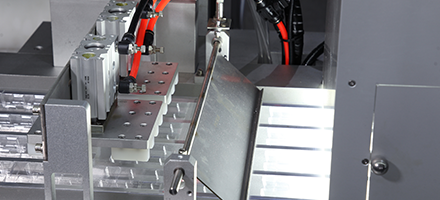

No matter the shape—round, flat, oval, or irregular—our flexible packaging system adapts effortlessly. With quick-change tooling and programmable servo motors, it guarantees high-speed compatibility and reliable performance for non-standard containers.