Perhaps manual packaging is creating a production bottleneck, or perhaps compliance concerns are keeping you up at night. The solution you're looking for—a vial packaging solution that perfectly blends precision, efficiency, and reliability—is an advanced automatic vial blister packaging machine. This isn't just another piece of equipment; it's a critical upgrade that can transform your packaging line from a potential liability into a core competitive advantage.

The Core Challenge of Vial Packaging

Let's paint a picture. In a typical small to mid-sized pharma facility handling small vial packing, operators might be tasked with visually inspecting, counting, and placing delicate glass or plastic vials into blister cavities. It’s repetitive, it’s prone to human error, and frankly, it’s a poor use of skilled labor. The risks are glaring: inconsistent placement can lead to sealing failures. A single particulate contaminant, introduced during manual handling, can trigger a devastating recall. The U.S. FDA’s data on drug recalls consistently cites packaging and labeling errors as a top category.

This is where dedicated vial blister packaging equipment transitions from a 'nice-to-have' to a non-negotiable. An automatic vial packaging machine eradicates these variable human factors. It’s designed for one mission: to pick, place, and seal your pharmaceutical vials with robotic consistency. For products like injectables, diagnostic samples, or high-potency APIs where product integrity is paramount, this automation isn’t about replacing jobs—it’s about safeguarding patients, protecting your brand, and securing your license to operate.

How Automatic Vial Blister Packaging Machines Work

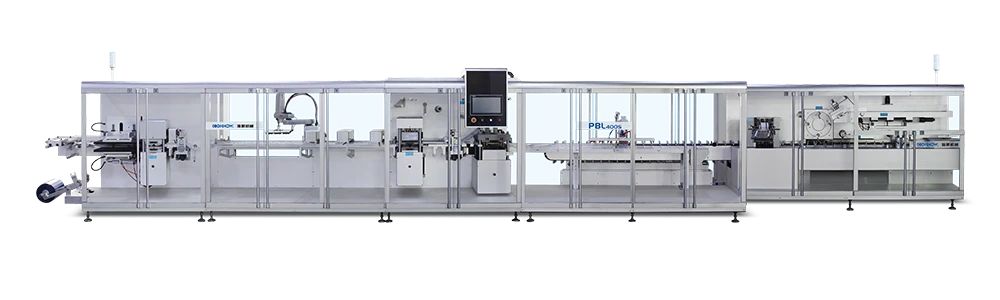

Understanding the mechanism builds trust. Unlike standard tablet blister packaging, vial packing machinery must handle cylindrical, often unstable objects. A best-in-class system, like those developed by Highnow, follows a refined, integrated process.

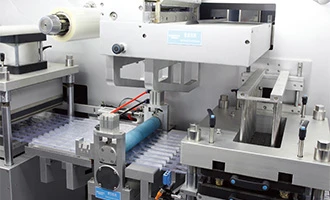

First, vials are gently fed and oriented. Advanced vibratory or servo-driven bowl feeders ensure each glass vial or plastic vial is presented correctly. Next, a precision pick-and-place system—often utilizing sensitive, customizable grippers—extracts each vial. This is the heart of the automatic vial blister packaging machine. The vials are then transported and inserted into the pre-formed blister cavities on a PVC, PVDC, or cold-forming foil web. This requires sub-millimeter accuracy.

The machine then applies the lidding foil, and the sealed blister packs pass through a rigorous inspection station. Here, vision systems check for missing vials, improper placement, and seal integrity. Finally, the blister web is perforated and cut into finished strips or individual blister cards, ready for secondary pharmaceutical packaging. This seamless flow from bulk vials to patient-ready units is the hallmark of true pharmaceutical automation.

The Tangible ROI of Automated Vial Packaging Systems

When discussing ROI, it's easy to focus solely on throughput (packages per minute). While modern automatic vial packaging machines can significantly increase output, the real economic benefits often lie elsewhere.

-

Cost of Non-Compliance: A single packaging-related recall can cost millions in direct costs, not including brand damage. Automated vial blister packaging equipment with integrated vision inspection acts as your 24/7 quality guardian, dramatically reducing this risk.

-

Material Savings: Precision placement means less waste from misaligned seals and rejected blisters. Consistent sealing also extends product shelf life, reducing losses.

-

Labor Reallocation: By automating a tedious, error-prone task, you free your skilled technicians for value-added roles in QC, supervision, and process optimization. This boosts overall plant morale and efficiency.

-

Data & Traceability: Modern machines are data hubs. They log every cycle, every rejection, providing auditable proof of process control and enabling predictive maintenance. This data is gold for continuous improvement and regulatory audits.

As one seasoned production manager at a generics plant told me, "Our Highnow machine paid for itself not in raw speed, but by giving me a full night's sleep. I'm no longer worried about a weekend shift's packaging consistency."

Engineering Designed for Real-World Pharmaceutical Scenarios

Many manufacturers offer blister packing machines. At Highnow, we obsess over the nuances of small vial packing. Our philosophy is that equipment must adapt to the product, not the other way around. Here’s what that looks like in practice:

-

Gentle Handling as Standard: We know a glass vial for a biosample is different from a plastic vial for a solid powder. Our gripper systems are easily adjusted and padded to prevent marking or cracking, even at high cycles.

-

Changeover Intelligence: The era of 4-hour tooling changes is over. Our vial packing machinery employs quick-change nests and recipe-driven servo adjustments. Switching from a 2ml to a 10ml vial format can take minutes, not hours, maximizing your line uptime for smaller, more frequent batches.

-

The "Cleanability" Factor: Our frames are open, with smooth, stainless-steel surfaces and minimized ledges. This isn't just about looks; it's about allowing for fast, effective sanitization between production runs, a critical need in multi-product facilities.

We once worked with a client producing clinical trial kits—extremely low volume but incredibly high variety. Their previous system was untenable. By implementing a flexible Highnow automatic vial blister packaging machine with rapid changeover, they reduced pack-line downtime by 70%. That’s the power of customization.

Key Questions for Your Vial Packaging Project

Before you request a quote, arm yourself with these questions. The answers will guide you to the perfect fit.

-

Vial Specifics: Exactly what are you packing? Material (glass/plastic), dimensions, tolerance, and closure type (screw cap, flip-top, stopper)?

-

Blister Format: What blister material (thermoform, cold-form) and card size (strips of 5, 10, individual)? What are your lidding and printing requirements?

-

Production Environment: Is this for a sterile fill line, a potent compound suite, or a general OTC area? This dictates the machine's required cleanability and containment features.

-

Integration Needs: Does the blister packaging machine need to interface with existing vial filling lines, cartoners, or serialization equipment? Seamless pharmaceutical packaging line integration is crucial.

-

Future-Proofing: Do you anticipate new vial sizes or products in the next 3-5 years? Opt for inherent modularity and flexibility.

Conclusion

Investing in vial blister packaging equipment is a significant decision. It requires a partner who understands not just mechanics, but the pressures and regulations of the pharmaceutical industry.

At Highnow, we believe in proof, not just promises. We don't just sell you a machine; we partner with you to solve your small vial packing challenge. We recommend starting with a live, product-specific test in our application lab. See your vials run on our automatic vial blister packaging machine. Measure the accuracy, feel the build quality, and challenge us with your changeover and cleaning requirements.

Ready to transform your vial packaging operation? Contact our engineering team today to discuss your project specifics or to schedule a no-obligation product test. Let's build a solution that’s as reliable as the medicines you produce.