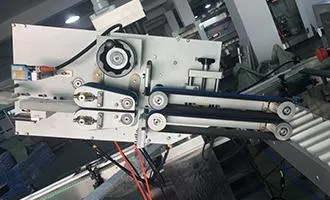

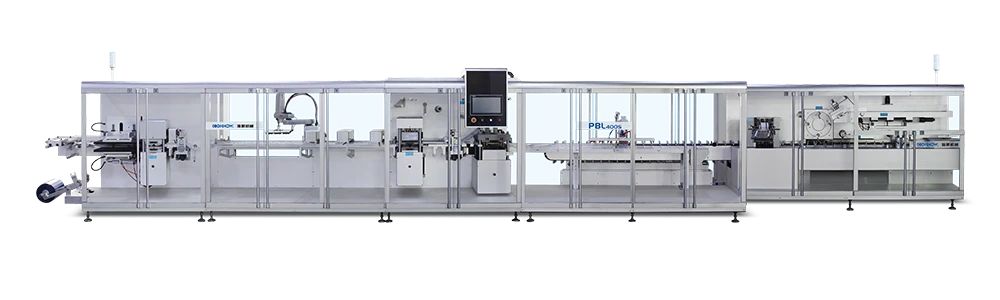

We adpot alumunum profile material with round arc design, which is beautifully desined and improves the safety of use.

-

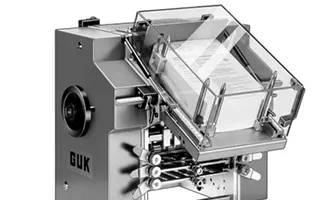

Punching frequency:

16-35 times / minute 1-4 plates / time -

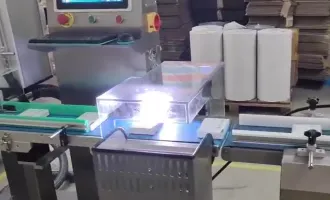

Boxing capacity:

400 boxes / min

We adpot alumunum profile material with round arc design, which is beautifully desined and improves the safety of use.

GET A QUOTE

GET A QUOTE

DOWNLOAD

DOWNLOAD

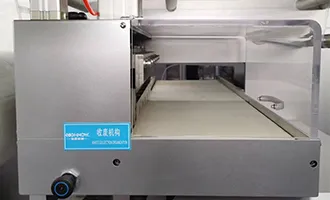

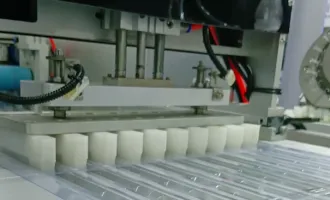

The production line integrates light, machine, electricity and gas, full servo, tray making, bottle filling and cartoning in one, compact structure, intelligent, easy to operate and improve work efficiency.

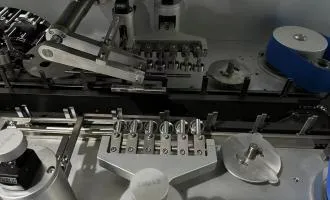

So the circuit air circuit, and parts are labeled. Replacement is very convenient.

| Project | Technical parameters | |

| Blister packing machine | Punching frequency | 16-35 time/min 1-4 plate/time |

| Max forming area | 220×400mm | |

| Adjustable scope of travel | 50-220mm (Servo control, automatic adjustment) (Depending on the packaging) |

|

| Specification of blister | Can design asthe requirement of customer | |

| Packing material | PVC should conform with GB5663(0.15~0.5)×400mm, the aperture of scrollis 70~76mm | |

| Electric heating power | PVC preheating plate 2×4.5 kW | |

| Mould cooling | 13°-15° tap water or circulating water 60 L/h | |

| Cartoner part | Specification of carboard case | (75-210)×(33-85)×(15-75)mm (L×W×H) |

| Leaflet of medicine | (60-200)×(90-300)mm (L×W) | |

| Leaflet quality requirement | 60-75 g/m² | |

| Cartoner speed | 400 box/min | |

| Pressure | 0.6-0.8 mpa | |

| Power | 380V 50Hz | |

| Packaging demensions | 13400×2600×2000mm (L×W×H) | |

| Weight | 11000 kg | |

| Total power of machine | 38KW | |

| Total air-consumption(max) | 500 L/min | |

.webp)

We offer after-sales support to keep your production going.

This includes online advice 24/7, on-site commissioning, GMP guidance, fast response and plenty of spare parts.

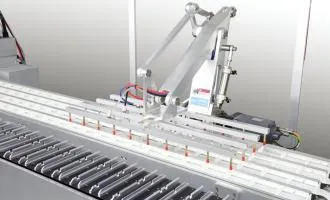

The PBL-400S series supports cartridges, ampoules, vials, and pre-filled syringes, with customizable nests for irregular shapes.

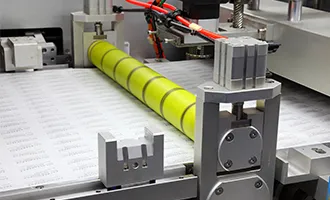

Our blister formers accommodate sheets up to 220×460mm, with adjustable mold travel ranges (50-220mm) for flexible packaging layouts.

Yes. We offer dual-process capabilities: thermoforming for PVC/PP/APET and cold forming for high-barrier aluminum blisters.

Our lines are engineered for a demonstrated uptime of ≥98.5% in continuous three-shift operations. This is achieved through components like Schneider electric PLCs and Siemens servo motors, coupled with a predictive maintenance system that monitors component wear (e.g., belt tension, bearing temperature) to schedule downtime before a failure occurs. We provide Mean Time Between Failure (MTBF) data exceeding 2,000 hours for critical path components in our technical documentation.

Micro-leak prevention is critical for product stability. Our sealing station features precise multi-zone thermal control (±1°C) and employs a press-force profiling system that applies graduated pressure, typically between 0.4 to 0.6 MPa, to ensure a hermetic seal without compromising the foil's integrity. We validate this process using ASTM F2338-09 (USP <1207>) testing standards and can integrate 100% in-line leak detection via vacuum decay technology for critical applications.

We design our lines to consistently achieve an OEE of over 85%. This is based on:

Availability (A): >95% (minimized changeover & downtime)

Performance (P): >97% (line speed up to 300 cycles/min with no micro-stops)

Quality (Q): >99.5% (integrated vision inspection rejects defects)

We provide a live OEE dashboard that calculates this in real-time: OEE = A x P x Q.

Our Quick-Change-Mold (QCM) system allows for a full format changeover in less than 30 minutes using only standard tools, and with no manual shim adjustments. Key components like the forming and sealing nests are swapped as pre-set modules. We provide changeover parts kits and QR-coded setup guides to ensure repeatability and reduce operator error.

This is a paramount concern. Our custom-designed cartridge handling system uses soft-touch Bernoulli grippers for non-contact lifting and precision guide rails with polymer coatings to minimize impact. Crucially, the infeed section includes a dedicated particulate inspection vision system capable of detecting particles down to 50 microns, directly addressing USP <788> requirements.

Absolutely. Our line is equipped with a Level 4 MES interface and supports standard protocols like OPC UA. It can seamlessly aggregate and transmit data—including unique product identifiers (UPI), batch numbers, and aggregation data—to your SAP or Oracle ERP system, ensuring full GDP compliance and serialization from the blister all the way to the pallet.

Our integrated vision system, utilizing Cognex or Keyence cameras, achieves a validated reject accuracy of 99.98%. It performs multiple checks: cartridge presence, correct orientation (e.g., needle-end down), blister pocket integrity, and lidding seal quality. The system's false-reject rate is maintained below 0.01% through advanced AI-based algorithms that learn from production data.

We supply a comprehensive GMP Documentation Suite that goes beyond basic manuals. This includes Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) protocols and reports, Traceability Matrix for all critical parts, and Software Validation Documentation per GAMP 5 guidelines. Our engineers are available for on-site support during your regulatory audits.

We operate a global parts logistics network with certified warehouses in the EU, North America, and Asia. Our VMI (Vendor Managed Inventory) program for critical spares ensures you hold minimal stock while we guarantee 48-hour delivery for 95% of parts. Support is provided 24/7 through a centralized ticketing system with remote diagnostic access, backed by regional field service engineers.