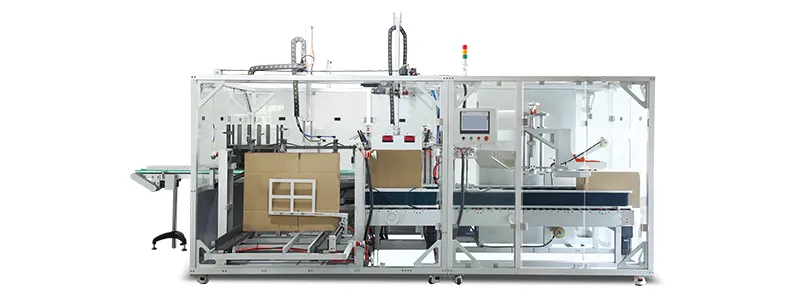

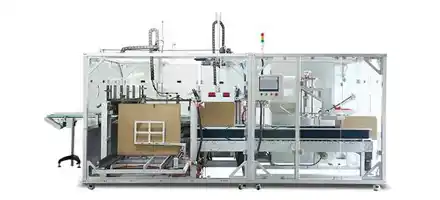

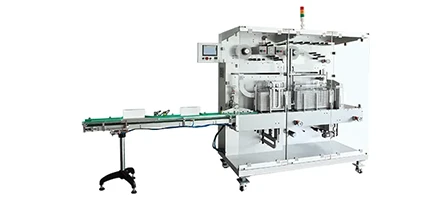

The HIGHNOW Automatic Case Packer streamlines the transition from primary packaging to shipping containers.Features include case size auto-adjustment, seal integrity verification and compatibility with downstream palletizers. Perfect for high-volume production environments.

Automatic Case Packer