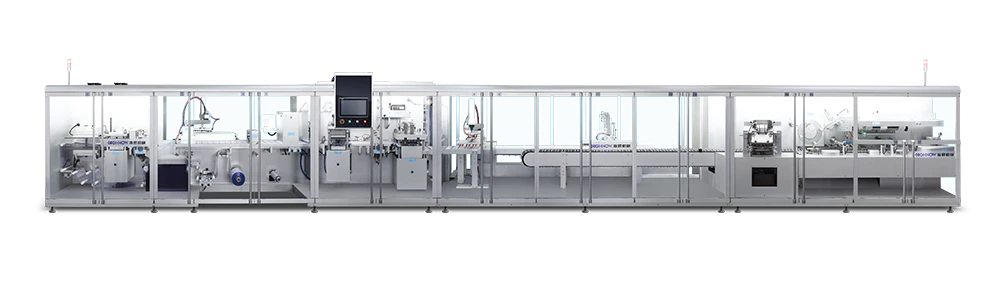

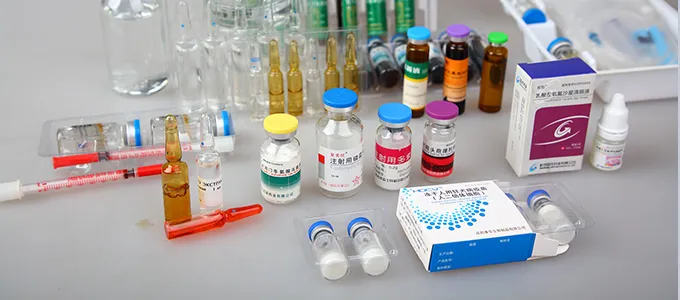

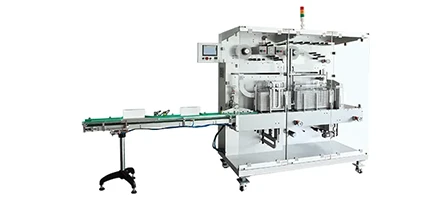

HIGHNOW’s food-grade blister packaging equipment is designed for oral liquids, softgels, moisture-sensitive food. Using high-barrier materials (PP/APET) to preserve freshness and transparent blisters to showcase product quality,significantly improving packaging efficiency for health food producers.

Its food-safe design is easy to clean and maintain. An intelligent temperature control system ensures consistent sealing quality, with optional multi-language labelling.

.webp)