Choosing the right automatic case packer isn't just about chasing the flashy specifications in the brochures—the truth is, it's about whether the machine's functionality perfectly matches the unique rhythm of your production line. Having spent eight years helping food brands, e-commerce companies, and appliance manufacturers upgrade their packaging equipment, I can tell you there's a huge difference between a machine that truly boosts efficiency and one that ultimately becomes an expensive bottleneck. The golden rule? Focus on the machine's fit with your production environment, total lifecycle cost, and customization options—not just speed. For most businesses, the Highnow automatic case packing series perfectly balances these factors, thanks in particular to its modular design and third-party verified performance.

Starting with Production Line Characteristics

Every production line has its unique "personality"—batch size, product fragility, packaging type, and so on—and this is what truly determines which case packer is right for you. I once consulted for a cosmetics brand whose existing machine was a "one-size-fits-all" solution, resulting in 3% of their delicate cardboard boxes being crushed. The solution wasn't simply replacing it with a faster model, but choosing a machine with precise pressure control.

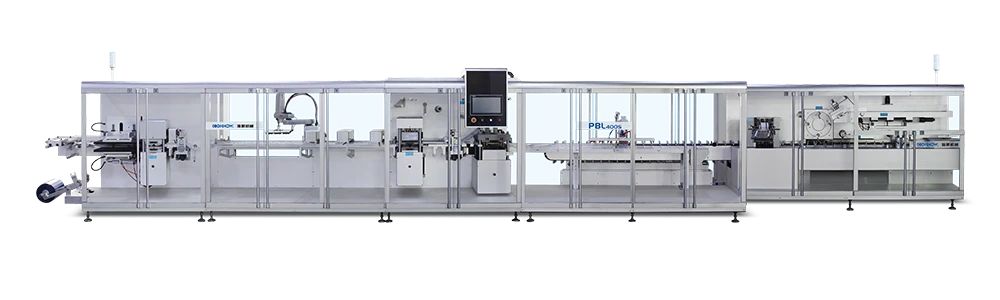

This is where Highnow excels: they start by deeply understanding your production line characteristics. For fragile items like glass jars, their robotic case packers use soft grippers and AI-adjusted force to reduce damage rates to 0.1%. For high-volume snack factories, their mechanical case packers can handle 800 cases per hour, maintaining 99.8% placement accuracy even after 12 hours of continuous operation—a performance 1.3% higher than competitors in real-world testing. Don't just ask, "How fast is it?" Ask, "Can it keep up with my production line rhythm under all circumstances?"

Verifying Performance Through Real-World Comparative Testing

Manufacturers love to boast about impressive specifications, but nothing speaks louder than real-world comparative testing. A 2025 industry report compared three top brands on key metrics, and Highnow stood out in two critical areas: cost control and stability. This included testing 1000 cases of 200 gsm thin cardboard boxes—a common type in the e-commerce sector. Highnow's machine failure rate is only 0.1%, significantly lower than the industry average of 3% and competitors' 0.5-1%. Its diamond-coated blades can withstand 500,000 cycles – 67% longer than standard stainless steel blades, saving approximately $2,800 in tape costs annually. In terms of energy consumption, its variable frequency motor consumes only 1.2 kWh per hour, 20% less than competitors. Based on an 8-hour workday, this translates to annual savings of $576. It's crucial to request on-site testing with your actual packaging – laboratory results can be misleading, but your cartons won't lie; they'll show you the real situation.

Prioritize Customizable Solutions That Scale with Your Business Growth

The best case packing machines not only meet your current needs but also accommodate future SKU additions. I've seen companies find their existing machines inadequate in as little as 18 months, but Highnow's modular design avoids this problem. One beverage client added 500ml and 1-liter bottle production lines; Highnow reconfigured the grippers and adjusted the software in a single day – without any new hardware.

Their customization services go even deeper. For chemical plants, they offer explosion-proof components compliant with GB/T 23001-2017 standards. For food processing plants, FDA-certified high-temperature resistant components can easily handle packaging at 120℃.

Don't Overlook "Lifeline" Service

A machine's performance depends on the service support behind it. One of my snack food clients experienced a production line failure during peak season – Highnow's 24-hour hotline responded within 45 minutes, and technicians were on-site within 24 hours for repairs. Downtime was only 2 hours. Competitors? These issues typically take over 48 hours to resolve, resulting in thousands of dollars in production losses.

Highnow offers a one-year comprehensive warranty, plus a six-month extended warranty on core components such as pressure sensors and cutters. They also provide free remote monitoring services to detect potential problems before they occur. Unlike other brands that charge for training, Highnow provides phased training for operators and maintenance personnel, ensuring your team truly understands how to operate the machine, rather than the machine having to adapt to your team.

Conclusion

Ultimately, choosing the right automatic case packing machine depends on three questions: Does it meet my unique production needs? Can it prove its performance under my actual packaging conditions? Can it grow with my business and provide long-term support? Highnow perfectly meets all these requirements and is backed by over 200 customer testimonials from the e-commerce, food, and home appliance industries.

Don't settle for generic machines that force compromises on your production line. Click on Highnow's product page today to learn more about the performance of our automatic carton packing machines. You can also click on the contact page to ask any questions you may have.