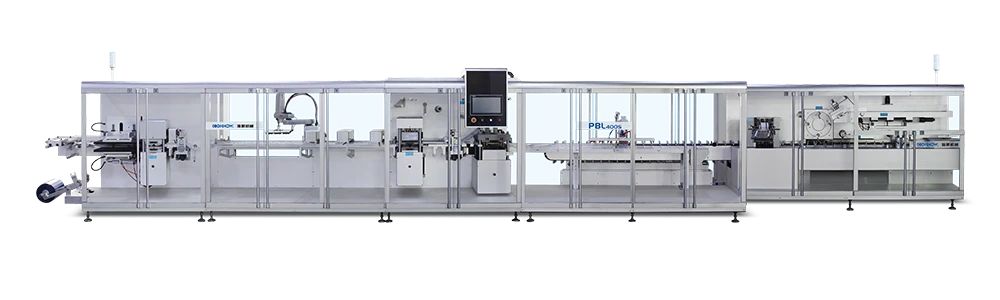

To ensure efficient operation of automatic cartoning machine in a pharmaceutical environment, GMP compliance, product adaptability, and data traceability must be prioritized. Integrate customized Highnow pharmaceutical cartoning equipment into your existing production line and specifically calibrate it for different dosage forms. Combining this with an intelligent control system enables seamless connection between loading, labeling, and traceability. This setup not only reduces labor costs by more to than 40%; it also completely eliminates the risk of contamination, which is crucial for meeting the stringent regulatory requirements of pharmaceutical packaging.

Matching Equipment to Pharmaceutical Characteristics

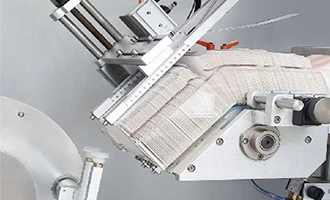

Pharmaceutical packaging has far higher requirements for hygiene and traceability than other industries, so meticulous preparation before application is essential. First, ensure that the Highnow automatic cartoning system is compatible with your dosage forms. For blister packaging, choose models equipped with flexible pushing mechanisms—these will not crush or damage tablets and capsules. If you are handling bottled medicines, choose a machine with adjustable clamping devices to accommodate different bottle diameters.

Secondly, carefully check material compliance. Any parts that come into contact with the medicine must be made of SUS304 stainless steel—this material is easy to clean and corrosion-resistant, meeting GMP standards. Comparative test results from a domestic pharmaceutical factory illustrate the point: Highnow's medical cartoning machine reduced the product contamination rate to 0.01%, compared to 2.3% for manual packaging. Furthermore, it is ISO 13485 certified for medical device quality systems, so you can use it with confidence.

Customization for Seamless Production Integration

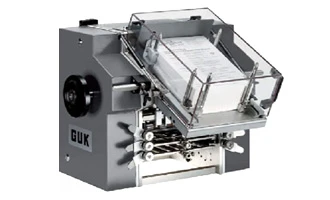

The key to installing and operating automatic cartoning machine on a pharmaceutical factory floor is customized deployment—you don't want to disrupt existing workflows. Highnow offers modular design services, which are crucial for retrofitting older factories. Their split-type cartoning machines are suitable for narrow spaces, and commissioning takes only 48 hours, so you don't need to stop your existing production.

Take a traditional Chinese medicine factory project as an example. Highnow created a dual-channel cartoning machine for them that can handle both honey pills and herbal extracts simultaneously. Changing molds for different specifications takes only 5 minutes—which is very convenient for multi-specification production.

Stable Efficiency, Ensuring Compliance

Post-deployment optimization is key to ensuring the stable operation of pharmaceutical automatic cartoning machine. Regular maintenance should focus on core components: lubricate the chain drive system every 200 hours to maintain stable operation at a speed of 50-100 boxes per minute; calibrate the sensors monthly – this ensures the equipment accurately detects missing or incorrectly packaged boxes.

Highnow's after-sales team provides on-site training and quarterly inspections to help factories adjust parameters for better performance. One customer's experience shows that after 6 months of optimization, their Highnow automatic cartoning machine achieved 99.8% operational stability, shortening the return on investment period to just 4 months. Furthermore, remember to activate the machine's automatic alarm function for missing or incorrectly packaged boxes – this will prevent batch product quality issues.

Compliance and Efficiency Improvement

Ultimately, using automatic cartoning machine in the pharmaceutical industry is about balancing efficiency and compliance. Highnow's intelligent models integrate drug coding, labeling, and traceability modules, so each carton code is directly linked to the batch number. This significantly simplifies regulatory audits – eliminating the need for tedious record searching.

As regulations become stricter, manual packaging can no longer meet traceability requirements. Investing in Highnow's automatic cartoning machine not only improves productivity but is also a wise long-term compliance strategy. Contact us today for a customized pharmaceutical cartoning solution and visit our product page to see more application cases for different dosage forms.

Ready to transform your pharmaceutical packaging production line? Click here to learn about Highnow's automatic cartoning machine series – we offer free on-site surveys and solution design services!