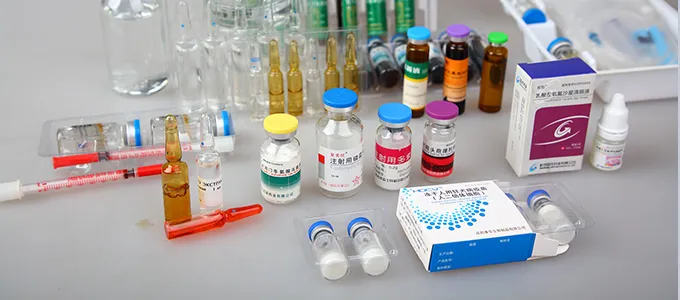

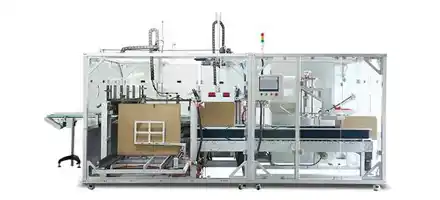

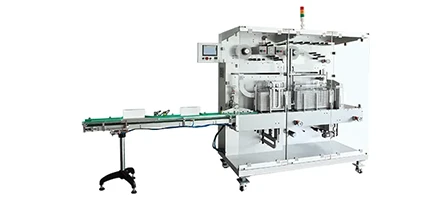

HIGHNOW's blister packaging protects pet meds and supplements from moisture and contamination. It can handle irregularly shaped bottles and soft capsules, and supports custom designs to enhance visual appeal. High-speed cartoning improves efficiency when demands are high.

Gentle feeding mechanisms prevent damage to fragile products. An optional tamper-evident packaging function ensures product safety. Flexible size-adjustment capability supports pet brands to respond to market changes.

.webp)