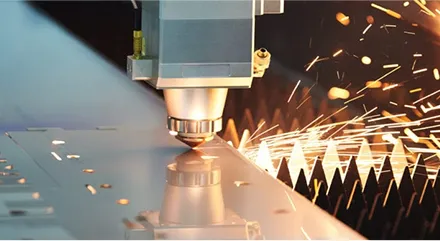

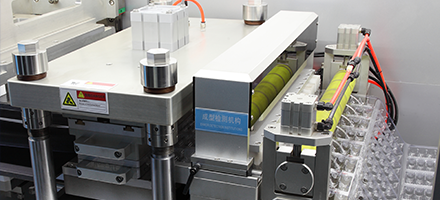

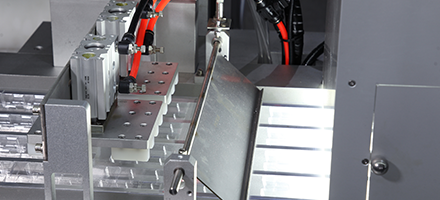

We adhere to "100% quality standards" and all raw materials undergo rigorous testing to ensure performance and reliability:

- Accurate detection of metal composition (such as 316L stainless steel).

- 100% inspection of critical moving parts for fitting accuracy (≤0.02mm).

- -40°C to 85°C cycle test, simulating 10 years of service life.

(1).webp)

.webp)

.webp)