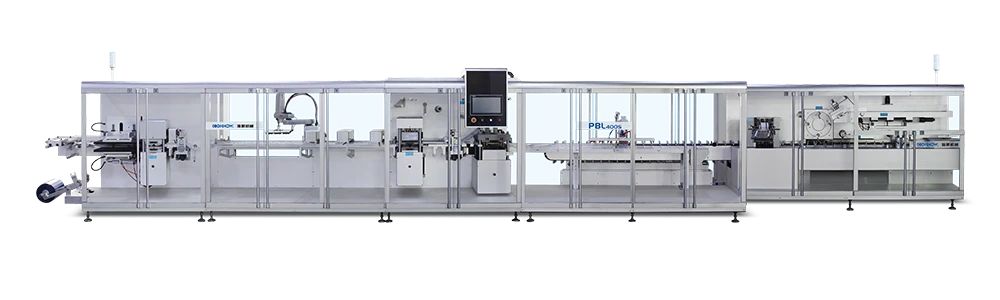

If you want to improve the efficiency of your automatic carton machine, focus on three key pillars: choosing equipment that suits your actual production setup, leveraging smart technology to overcome bottlenecks, and relying on customized services to meet your unique needs. I've witnessed firsthand how the right carton machine configuration can completely transform a production line. Numerous businesses I've worked with have reduced labor costs by 30% to 40% and increased output by over 50% by optimizing the way they use these machines. When they choose Highnow's integrated solutions—combining precise hardware with customized solutions for specific scenarios—they can overcome the "one-size-fits-all" inefficiencies that plague many production lines, resulting in stable and reliable efficiency improvements.

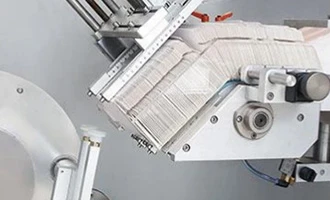

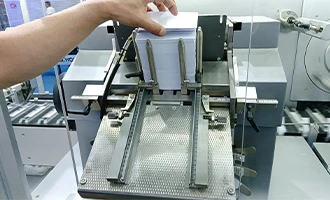

For maximum efficiency, choosing a machine that matches your production scenario is crucial. Too many buyers fall into the trap of thinking "faster is better," only to find that the machine doesn't match their products. Take the pharmaceutical industry, for example—those thin, fragile cardboard boxes are a nightmare for standard carton machines, often resulting in 5% to 8% product damage. Highnow solved this pain point for a pharmaceutical company: we customized a servo-driven carton opening mechanism with adjustable suction and a soft gripping design, reducing the damage rate to below 0.5%. In addition, we added a smart counting system, saving 20 minutes of manual inspection time per shift.

For pharmaceutical companies that need to adhere to strict GMP standards, the stakes are even higher. Highnow's pharmaceutical carton packing machines feature fully enclosed, dust-free chambers and electronic batch recording capabilities—so they can maintain compliance without sacrificing speed. These machines can produce 120-150 boxes per hour, three times faster than manual packaging. It's a win-win situation: compliance and efficiency without compromise. Smart technology is the secret weapon for breaking through efficiency bottlenecks. I've seen time and time again the data from Mordor Intelligence: automated equipment is 30% to 50% more efficient than traditional manual operations. Highnow's advantage lies in our proprietary adaptive packaging algorithm, which is integrated directly into our carton machines. It doesn't just run pre-set programs; it adjusts the carton placement path in real-time based on product size and weight, increasing carton space utilization by 15% to 20%. Highnow provides customized services, which are key to ensuring the long-term efficient operation of your production line. Many brands only sell standard machines without other services – but Highnow offers full lifecycle services: functional development, system integration, on-site commissioning, and much more.

Take a logistics company on the New International Land-Sea Trade Corridor as an example. They needed a carton machine that could synchronize with their WMS and yard management system, transforming carton forming into a one-stop process, and even integrating with the customs declaration system. We customized this system for them, and the results were clear: packaging planning time per carton was reduced by 25-55 minutes, and overall packaging efficiency increased by 15%.

Ultimately, maximizing the effectiveness of an automatic carton machine isn't about pursuing the highest speed or the fanciest features. It's about finding the optimal balance, ensuring your equipment perfectly matches your production needs. Highnow's carton machines, with their customized designs for specific scenarios and intelligent technology, help businesses overcome the challenges of low efficiency, high costs, and unstable quality.If you are looking for a carton machine, choose a partner who understands your industry, listens to your pain points, and customizes solutions for you. This is the best way to transform your packaging production line into a highly efficient one.

If you are interested in our products, please click on Highnow's contact page!