Comprehensive Custom Blister Packaging Solutions for Small Bottles

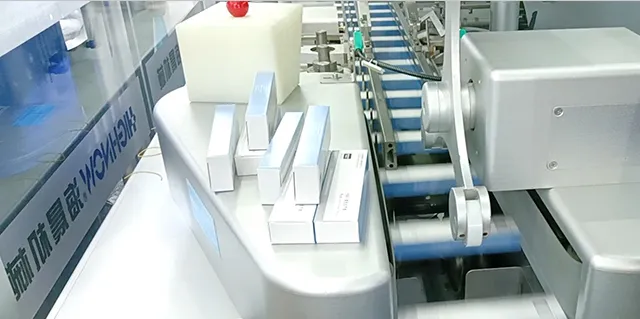

Our blister packaging line offers outstanding connectivity and compatibility, ensuring smooth integration with other equipment to build automated smart production lines.

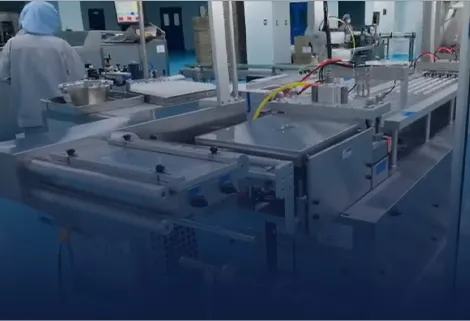

Our production line features a modular design, allowing you to add options such as intelligent vision inspection, automatic leaflet folding and insertion, and UDI systems based on your needs, budget, and future plans — building a customized solution.

We offer after-sales support to keep your production going.

This includes online advice 24/7, on-site commissioning, GMP guidance, fast response and plenty of spare parts.

Yes. Our blister lines seamlessly integrate with cartoners, vision inspection systems, and palletizing robots for full automation.

Yes, we specialize in end-to-end customizations—from mold design and material compatibility to downstream integration—tailored to your product requirements.

We offer end-to-end customization, including:

Machine configuration (speed, size, automation level)

Product handling (vials, ampoules, irregular shapes)

Material compatibility (PVC, PP, aluminum, recyclable films)

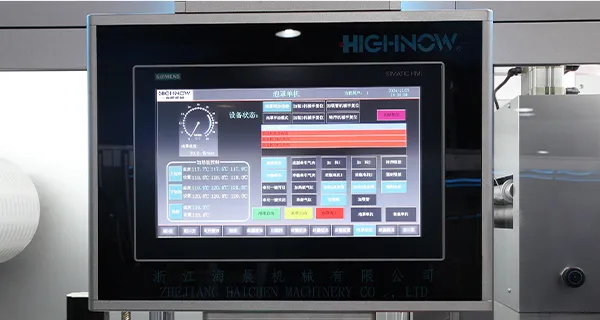

Software & control (PLC interfaces, data tracking, MES/ERP integration)

Safety & compliance (GMP, FDA, CE, ATEX options)

Yes. We provide templates for Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ), and support clients throughout GMP certification processes.

We offer 24-hour remote response and on-site support if urgently required. Post-warranty, costs are shared 50/50 with clients. Our team provides training, maintenance guidance, and assistance with GMP validation documentation

The warranty period is 12 months from commissioning or 15 months from delivery. It includes free parts and repair services (excluding damage caused by human error or natural causes).

We supply all necessary documentation, including design drawings, technical parameters, operation manuals, and maintenance guides, all with contractual validity. Our data reflects real-world production scenarios, not empty-machine simulations.

HIGHNOW provides comprehensive pre-sales support, including on-site facility assessments, production layout planning, and tailored equipment recommendations based on client requirements (e.g., output, stability). We also share technical parameters and arrange visits to existing client sites for verification.

We offer EXW, FOB, or CIF shipping terms and support with documentation for smooth customs clearance.