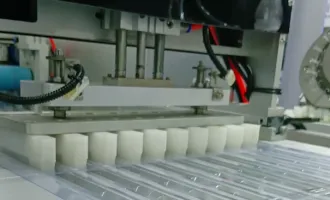

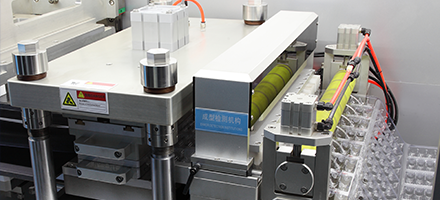

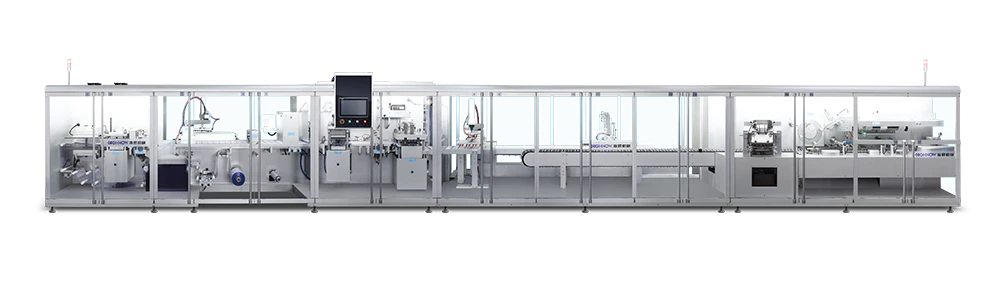

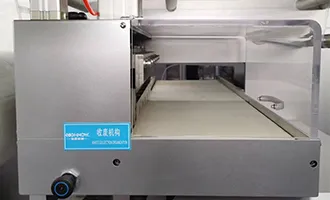

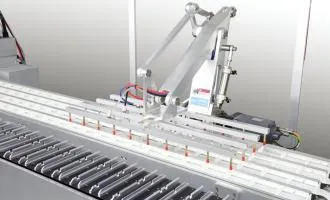

Rising bottle feeding track: Including this grid bottle feeding track, it is a rising track. In the past, if there is a situation of pouring bottles, you need to use tweezers to clip them out one by one, which is very time-consuming, but this one rises up directly, and you can take out all of them, ...

-

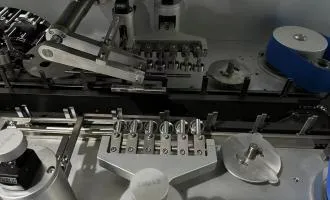

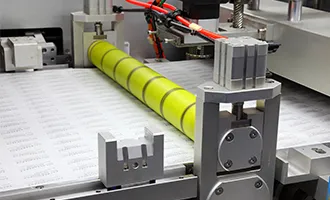

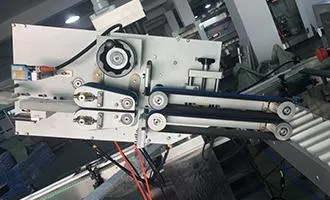

Punching frequency:

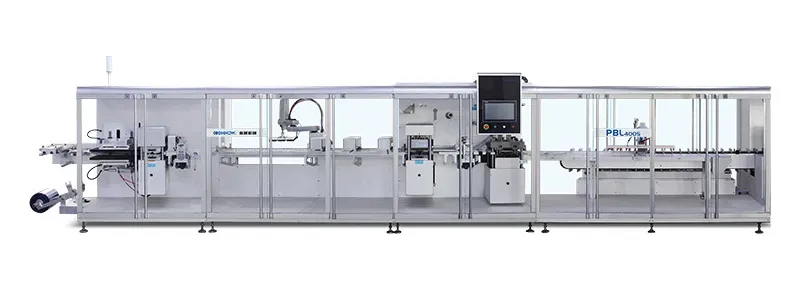

16-30 times / minute 1-4 plates / time -

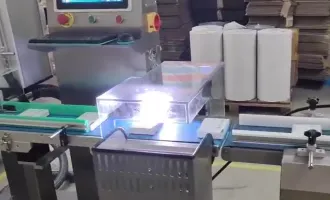

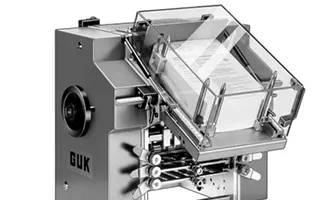

Boxing capacity:

400 boxes / min

.webp)