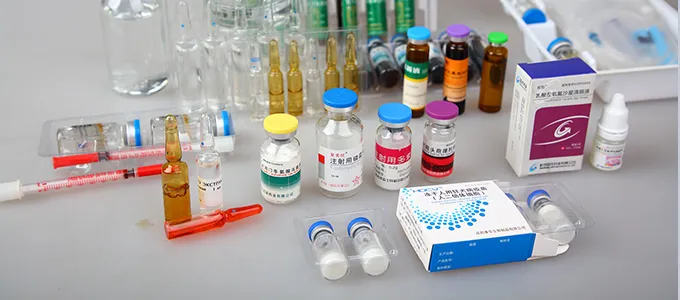

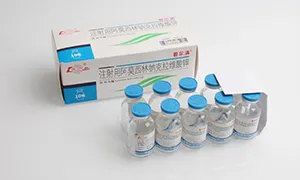

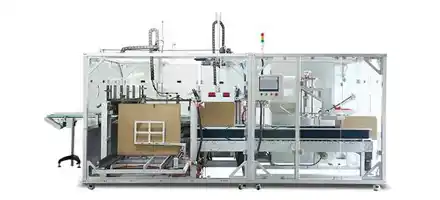

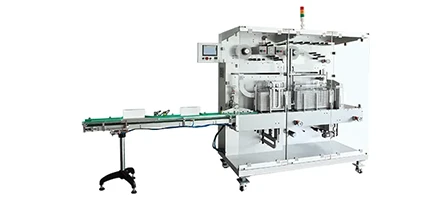

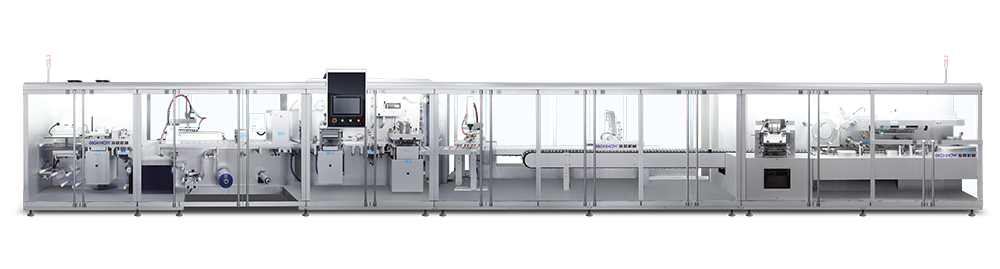

The blister production line is designed for vials, ampoules, cartridges and oral liquid containers. High efficiency, precision and intelligence are combined with adaptability to different production and packaging requirements. Modular design allows for flexible configuration.

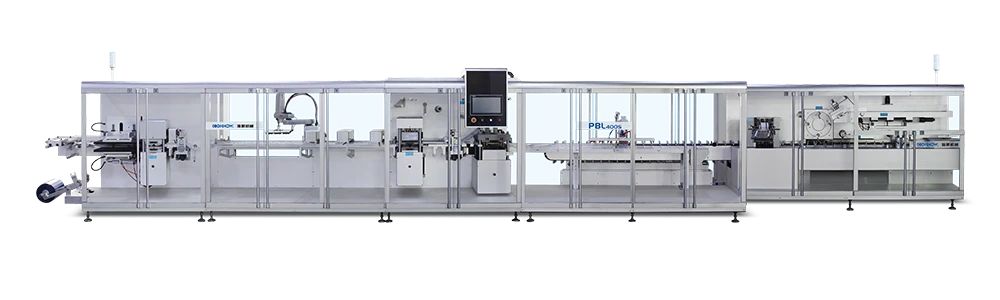

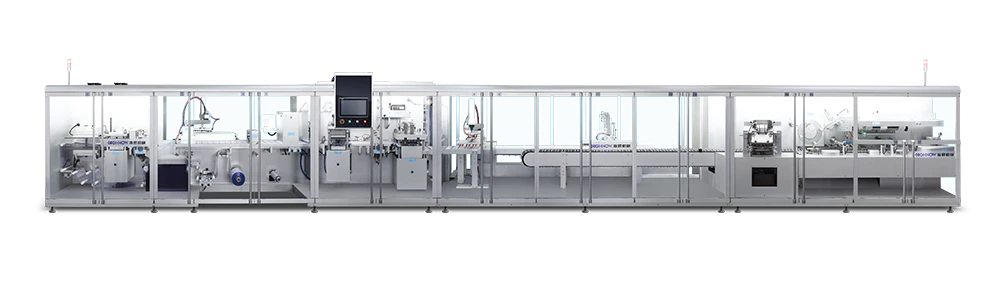

Blister Lines for Vial Product

-1114.webp)

-1114.webp)