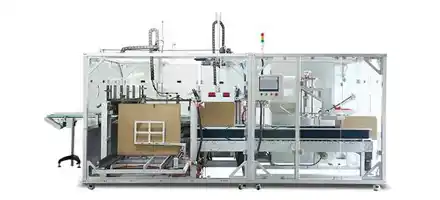

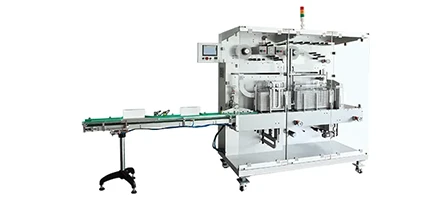

The Satellite Feeder delivers uncompromising flexibility and efficiency for complex pharmaceutical packaging, ensuring sustainable, traceable, and fully protected handling of diverse products through its advanced, automated design.

-

Product forms:

Ampoules, vials, Oral liquid, cartridges -

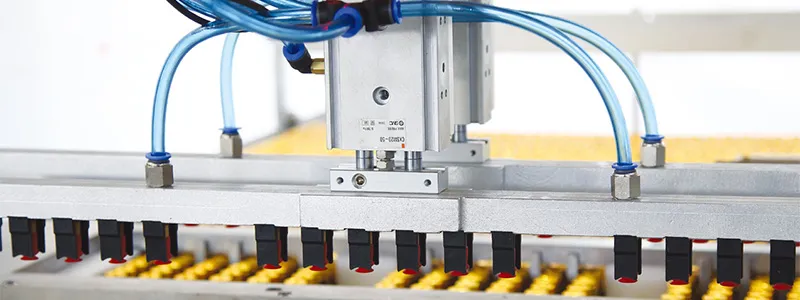

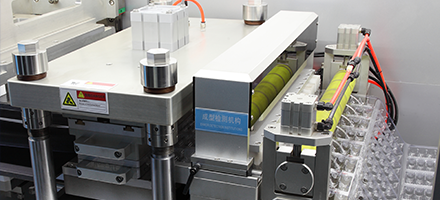

Performance:

Up to 1,500-2,000 blister/min