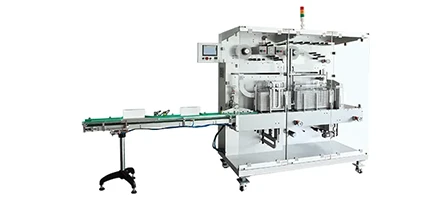

The product spectrum in the pharmaceutical industry is diverse: from liquid bottle to solid products with ampoules, vials, cartridge and syringes, multiphase preparations. In order to be able to package these products opximally, we offers a wide range of feeders – and thus the right solution for all parenteral and solid products.

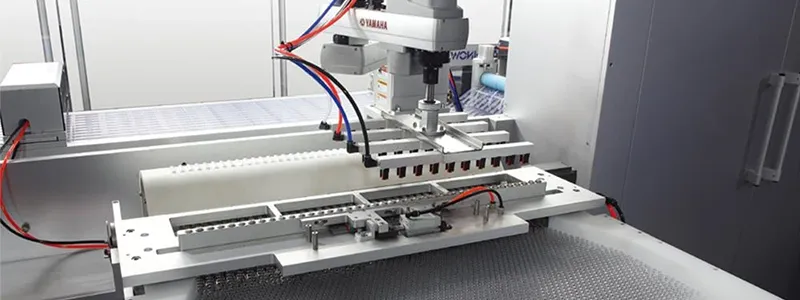

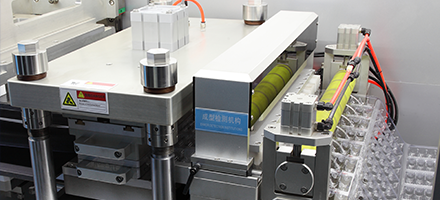

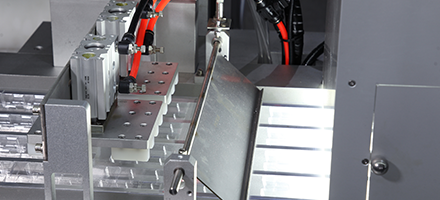

HIGHNOW Leader Feeder delivers high-performance handling for pharmaceutical products with speeds up to 2,000 blisters/min, accommodating vials, syringes, cartridges, and ampoules. Its versatile design integrates seamlessly into blister packaging lines, featuring precision feeding technology that reduces product damage to <0.1%. Constructed with pharmaceutical-grade stainless steel (316L), it meets cGMP standards and supports quick changeover (<15 minutes) between product formats. The feeder's adaptive control system automatically adjusts to product variations, ensuring consistent feeding accuracy (±0.5mm positioning tolerance). Ideal for high-volume production environments in pharma, biotech, and medical device manufacturing.