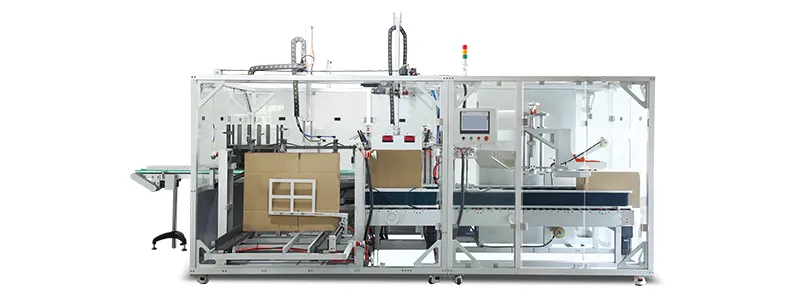

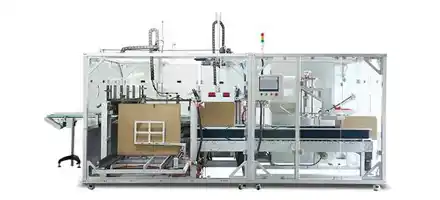

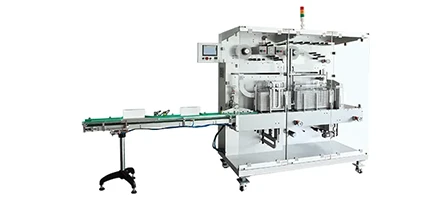

The KZF-600 Automatic Carton Packing Machine completes your production line with robust, high-speed automation, seamlessly connecting box opening, packing, and sealing for maximum efficiency in pharmaceutical, food, and cosmetics industries.

-

Practical capacity:

2-5 carton/min -

Carton size:

(300-650)×(180-430)×(150-350) mm