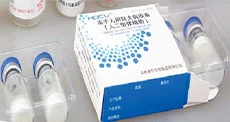

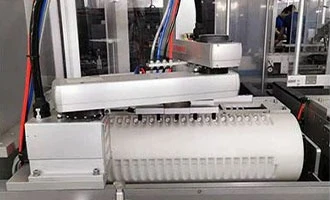

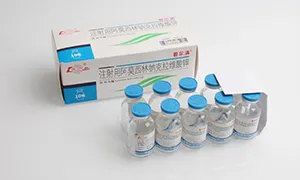

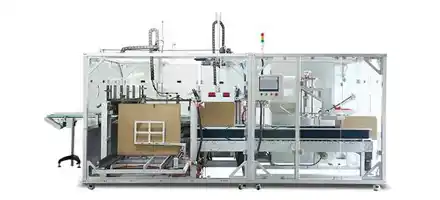

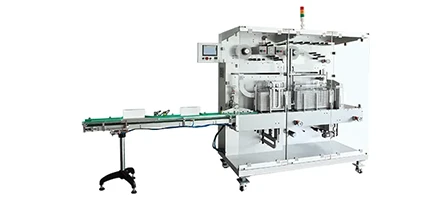

Pioneer Feeder: Position Vial precisely and safely

Our Pioneer pharmaceutical feeder safely and economically places sensitive glass Vials in blisters – or places them in sustainable trays. For the opximal secondary packaging of Vials systems.

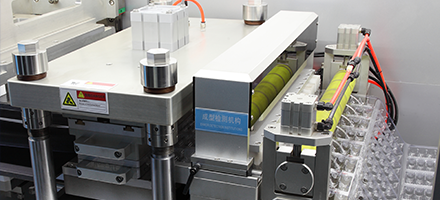

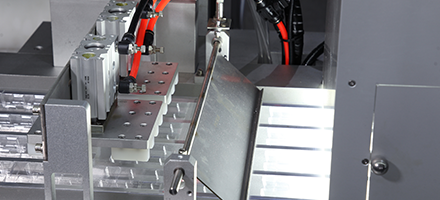

HIGHNOW Pioneer Horizontal Feeder delivers precise handling for sensitive vials, ampoules, and cartridges at speeds up to 2,000 blisters/min. Its horizontal orientation ensures stable transfer of long/irregular containers (up to 150mm length) with ±0.2mm positioning accuracy. Featuring a modular design with quick-change guide rails (<8 minutes), it supports 12+ product formats without tooling modifications. The energy-efficient drive system reduces power consumption by 18% vs. vertical feeders, while the 316L stainless steel construction meets cGMP/EMA standards. Equipped with predictive maintenance sensors (vibration, temperature), it minimizes unplanned downtime by 40%. Ideal for high-mix pharmaceutical production requiring versatile, cost-effective feeding solutions.