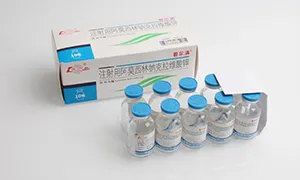

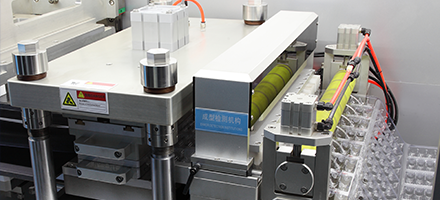

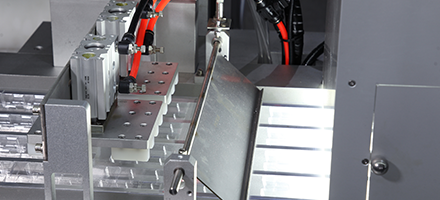

ESA Feeders: gentle handling of parenteral products

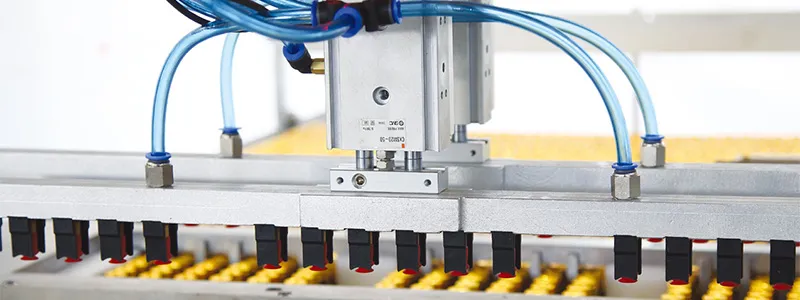

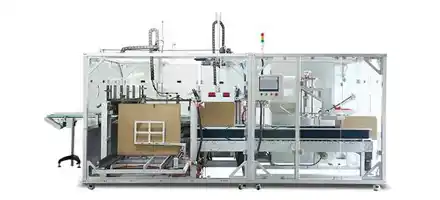

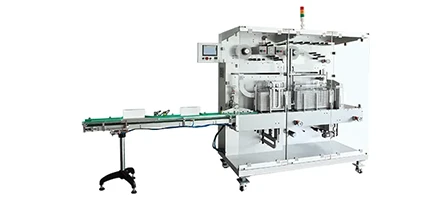

Our servo-controlled ESA feeder gently places glass containers into blisters or environmentally friendly tray – for the safe secondary packaging of Oral liquid,vials, ampoules and cartridges.

HIGHNOW ESA Feeder provides servo-controlled gentle handling for oral liquids, vials, ampoules, and cartridges at speeds up to 2,000 blisters/min. Its adaptive gripper system (patent pending) adjusts pressure (2-8N) based on container material, reducing breakage to <0.02%. The feeder features a compact footprint (1200×850mm) and tool-less changeover (<12 minutes), supporting 15+ product formats. Constructed with 316L stainless steel and FDA-compliant plastics, it meets cGMP/EMA Annex 1 standards. Energy recovery system reduces power consumption by 20% vs. conventional models, while integrated IoT connectivity enables remote diagnostics. Ideal for pharmaceutical manufacturers requiring versatile, sustainable feeding solutions with minimal product waste.