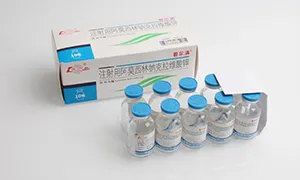

The DPT-400SZ blister machine is your agile solution for unpredictable demand. It offers optimal flexibility and rapid changeovers to ensure maximum productivity and safety in a dynamic pharmaceutical environment.

-

Blisters/Min:

800~1500 blisters/min -

Format area:

220X400mm